ESCO - STL/SC-8127-M4.5 - Soft Capsule® Soft Wall Cleanroom ISO Class 6* (US Federal Standard Class 1000)

Features

- Cleanroom ceiling grid enables flexible placement of fan filter units. Non-particulate shedding powder coated steel panels are provided to cover empty bays.

- Provides ISO Class 5, 6, or 7 environment (depends on client specifications) via high quality HEPA filters utilizing an improved mini-pleated separation technique to maximize surface area, improve efficiency, and extend the filter life.

- Centrally mounted control panel enables rapid start-up of fan filter units and lighting.

- The energy efficient external rotor motor design reduces operating costs and has extremely low noise and vibration levels, improving the working conditions in the cleanroom.

- Isostat™ vinyl curtains isolate the cleanroom from the ambient environment, while allowing easy passage of materials and personnel in and out of the cleanroom area.

- Cleanroom grade construction utilizing fully-welded, reinforced, steel tubular sections. Structure is finished with an abrasion-resistant oven-baked powder coat.

- Entire structure is free-standing and does not require any suspending ceiling supports.

- Built-in warm white, 5000k lighting provides excellent illumination of the cleanroom, and reduces operator fatigue.

Applications

- Pharmaceuticals, Grade A filling suites

- Medical devices, plastic injection moulding

- Electronics assembly

- Contact lens packaging

- Hospital pharmacy (USP 797)

- Biotechnology

- Nanotechnology

- Aerospace

- Quality control

- Food industries

Principle

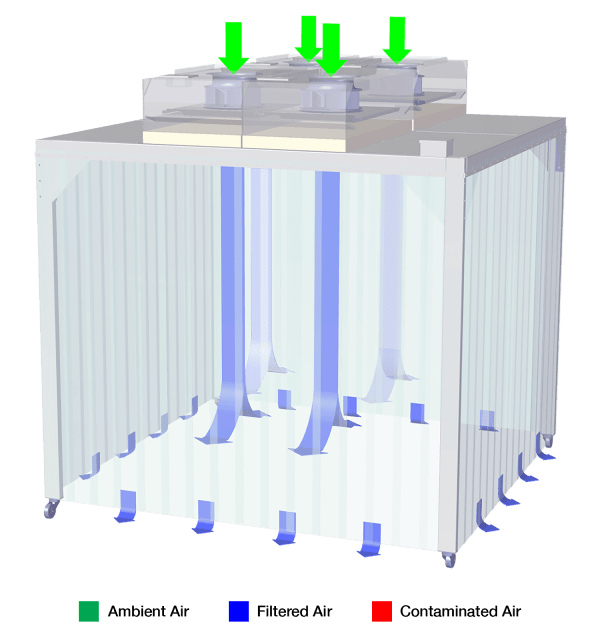

- Room air is taken in from the top of the cleanroom through a disposable pre-filter with 85% arrestance; this serves to trap larger particles and increase the life of the main filter.

- Air is forced evenly across the HEPA filter(s); the result is a stream of clean laminar air within the work zone; this dilutes and flushes all airborne contaminants from the interior.

- A nominal filter face velocity of 0.45 m/s or 90 fpm ensures that there is a sufficient number of air changes within the cleanroom in order to maintain cleanliness.

- The purified air travels downward within the interior in a vertical, unidirectional stream, and leaves the cleanroom close to floor level at the perimeter.

- The cleanroom is positively pressurized to prevent ingress of airborne contaminants from the external environment.

Options

- All stainless steel construction

- Leveling feet

- Complete factory test and certification, including airflow, filter integrity, particle counting, light and noise tests

- Extensions for existing Soft Capsule cleanrooms

Specifications

Overview

-

Nominal Height:8.6" (21.84 cm)

-

Nominal Width:8.29" (21.06 cm)

-

Nominal Length:12.26" (31.14 cm)

-

Internal Height:7" (17.78 cm)

-

Internal Width:8" (20.32 cm)

-

Internal Length:12" (30.48 cm)

Technical Data

-

Power Consumption:870 W

-

No. of FFUs:3

-

Air Volume:3450 m3/h (2040 cfm)

-

Shipping Dimension (W x D x H) (Unassembled):12.47' x 3.02' x 1.64'

-

Shipping Volume:1.75 m3