ESCO - EQU/06-ESUS - Enterprise™ Laminar Flow Single Straddle Unit

Features

Esco Enterprise™ Laminar Flow Straddle Unit, Single/Double (ESUS/D) is the leading solution for industrial process protection. It is also suitable for large-scale industrial processes which typically require multiple units to be connected in an assembly line configuration.

Maintained with a vertical laminar flow of air, the unit is available in either single or double-sided models. In comparison to horizontal laminar flow designs, the vertical laminar airflow of the unit generates less turbulence around large pieces of equipment.

As a cost-saving boost to cleanrooms, the straddle unit provides an ultra-clean environment directly at the process level and may easily be placed in an ISO Class 7 cleanroom. This allows the elimination of initial and operating costs which are associated with full-sized ISO Class 5 or better cleanrooms.

Esco Pharma provides the highest quality of construction and manufactures a wide range of equipment for the most demanding cleanroom applications.

Low Noise

Quiet and smooth operation with reliable permanently lubricated direct drive centrifugal blowers.

Effective Filtration System

Long-life HEPA filter/s are equipped for the supply airflow for sterile/aseptic work zone environment created for optimum product protection. Also, an additional disposable pre-filter on all models traps large particles in the inflow air prior to reaching the main filter, protecting it against damage and prolonging its life.

Easy-to-Clean Optional Worktop

The optional worktop surface is constructed of stainless steel, making the work zone easy to clean.

External Isocide™ Antimicrobial Powder Coating

Esco antimicrobial coating on all painted surfaces minimizes contamination.

Single/Dual and 4'/6' Configurations

Available in single, double, 1.2 (4') and 1.8 meter (6') models.

Connectable Units for Large-Scale Processes

Multiple units may be connected for production line applications.

Reduced Vibration

Units are floor-mounted with an optional stainless steel worktop isolated from the mainframe to reduce vibration.

Excellent Illumination

Built-in warm white, electronically ballasted, 5000k lighting provides excellent illumination of the work zone and reduces operator fatigue.

Enhanced Operator Comfort

Transparent polycarbonate side panels enhance visibility and create a more comfortable work environment for the operator as opposed to conventional stainless steel or painted steel sides.

Guaranteed Cleanroom Compatibility

All straddle unit components are cleanroom compatible.

Applications

- Cleanrooms, electronics assembly, semiconductors, pharmaceutical, aerospace, and medical devices industries

- Mycology and food microbiology

- Plant and mammalian cell culture

- Clinical pharmacy and hospital use

- Applications benefiting from the isolated work surface frame design which virtually eliminates vibration (good for weighing processes)

- Handling of non-biohazardous materials where operator protection is not required

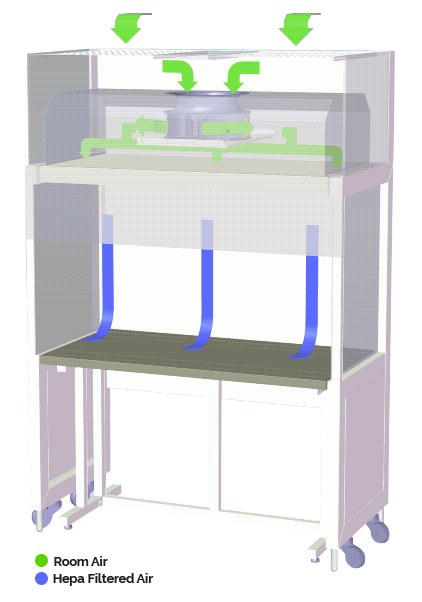

Principle

- During operation, room air is drawn through the top of the straddle unit via a disposable polyurethane prefilter with 20% arrestance, trapping larger particles and increasing the life of the main filter.

- The air is then forced evenly through the HEPA filter with a typical efficiency of >99.999% at 0.3 micron particles, resulting in a unidirectional stream of clean air projected vertically over the internal work zone. All airborne contaminants are flushed and diluted, resulting in a particulate-free work environment.

- The purified air then leaves the storage area across the entire open front of the straddle unit.

- A nominal filter face velocity of 0.45 m/s (90 fpm) ensures that there is a sufficient number of air changes within the enclosed area of the straddle unit in order to maintain cleanliness.

Accessories

- Prefilter

- Ebm-papst® Blower

- Fluorescent lamps

- Acrylic Side Wall

- Leveling Feet

- Caster Wheel

- Pressure Gauge

- Operating Switch

- Isolated Stainless Steel Worktop

Specifications

Overview

-

Nominal Height:78.7" (199.9 cm)

-

Nominal Width:76.7" (194.82 cm)

-

Nominal Length:29.1" (73.91 cm)

-

Internal Height:28.3" (71.88 cm)

-

Internal Width:72" (182.88 cm)

-

Internal Length:25.4" (64.52 cm)

Technical Data

-

Nominal Size:1.8 meter (6')

-

Usable Work Zone:1830 x 645

-

Initial Airflow Velocity:Average of 0.45 m/s or 90 fpm (+/- 20%)

-

Air Volume:1810 m3/h

-

Pre-Filter:Washable non-woven polyester fibers with 90% arrestance and 20% efficiency

-

HEPA Filter Typical Efficiency:99.99% at partical size 0.3 µm

-

Sound Emission Per IEST-RP-CC002.2:63.5 dBA

-

Fluorescent Lamp Intensity at Zero Ambient:1000 Lux

-

Net Weight:300 kg (660 lbs)

-

Shipping Weight:360 kg (792 lbs)

-

Shipping Dimensions, Maximum (W x D x H):2150 x 950 x 1610 mm (84.6" x 37.4" x 63.4")

Cabinet Construction

-

Main Body:1.5 mm (0.06") electro-galvanised steel with white oven-baked IsocideTM epoxy powder-coated finish.

-

Work Zone:1.2mm (0.05") 18 gauge stainless steel grade 304

Electrical (220-240 VAC, 50Hz, 1ø)

-

Cabinet Full Load Amps (FLA):4A

-

Cabinet Nominal Power:628 W

-

Cabinet BTU:2143