ESCO - EAS - Infinity® Esco Air Shower Pass Box

Product Range

| SKU | Name |

|---|---|

| EAS-PB-U1 | ESCO - EAS-PB-U1 - Infinity® Esco Air Shower Pass Box with UV (Switch, Interlock) Operation |

| EAS-PB-SS-U1 | ESCO - EAS-PB-SS-U1 - Infinity® Esco Air Shower Pass Box, Electromagnetic Interlock, With UV (Switch, Interlock) Operation Stainless Steel 304 |

| EAS-PB-SS | ESCO - EAS-PB-SS - Infinity® Esco Air Shower Pass Box, Electromagnetic Interlock Operation Stainless Steel 304 |

| EAS-PB | ESCO - EAS-PB - Infinity® Esco Air Shower Pass Box |

Features

- Built-in air shower significantly reduces surface contamination on materials entering or exiting the controlled environment.

- Materials entering or exiting the controlled environment are "scrubbed" by high velocity ULPA-filtered air jets with velocities of 18-30 m/s (3543-5906 fpm).

- An array of stainless steel nozzles direct high-velocity jets within the chamber.

- Contaminated air is then drawn through the base within the unit, filtered and recirculated.

- Air shower duration is adjustable up to 2 mins. Standard factory pre-set is 12 seconds.

- Electrical interlocking door mechanism.

- The air shower is constructed of electrogalvanized steel with white oven-baked epoxy-polyester Isocide™ antimicrobial powder coated finish.

- The pass box base surface is constructed of perforated stainless steel 304, making it easy to clean.

- Polycarbonate viewing windows provide a clear view of the internal chamber.

- Esco Air Shower Pass Boxes use German-made ebm-papst® permanently lubricated, centrifugal motor/blowers with external rotor designs.

- Selected for energy efficiency, compact design, and flat profile, the completely integrated blower assembly optimizes motor cooling, with unified rotating parts and overall component balance for smooth, quiet, vibration-free operation.

Key Benefits

- Energy Efficient

- SS 304 nozzles

- SS 304 base surface

- Acrylic doors

- Disposable prefilter

Principle

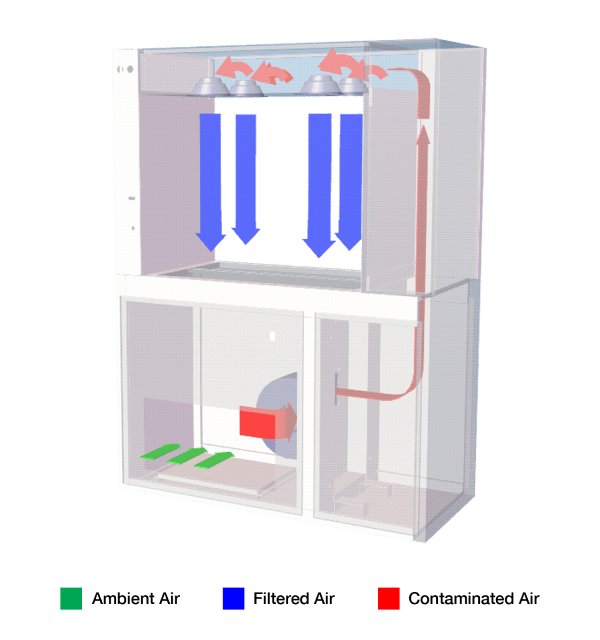

- Air is forced by the blower(s) through ULPA filter(s) which are >99.999% efficient against particles of 0.3 microns.

- Filtered air is ejected through nozzles at high velocities into the chamber. These turbulent air streams disperse particulate matter on all surfaces.

- Dispersed particulate matter migrate with the air stream towards the lower areas in the air shower chamber.

- The air is continuously filtered and recirculated.

Accessories

- Optional UV lamp

- Full stainless steel construction