ESCO - EAS-B9-EUS - Cleanroom Air Shower (B-Series)

Product Range

| SKU | Name |

|---|---|

| EAS-2B9-EUS | ESCO - EAS-2B9-EUS - Cleanroom Air Shower (B-Series) |

| EAS-3B9-EUS | ESCO - EAS-3B9-EUS - Cleanroom Air Shower (B-Series) |

| EAS-1B9-EUS | ESCO - EAS-1B9-EUS - Cleanroom Air Shower (B-Series) |

Features

Esco Air Showers (EAS) is a self-contained chamber strategically positioned at cleanroom entrances and other controlled environments. These chambers minimize particulate matter from infiltrating the clean space.

As personnel or materials pass through, the EAS "scrubs" by high velocity HEPA-filtered air jets with velocity of 18-30 m/s (3,543 - 5,906 fpm). The contaminated air is drawn from the base, filtered, and then recirculated into the chamber maintaining a clean environment.

Esco is the pioneering company for the manufacture and construction of cleanroom air showers with different applications in the following areas:

- Micro-electronics

- Semi-conductors

- Pharmaceutical

- Spray painting

- Laboratory animal research

- Food markets

With greater than 40 years of experience in the industry, Esco is consistently manufacturing and supplying reliable air showers and clean air solutions to reduce the potential for cross-contamination and enhance cleanroom integrity.

High-Velocity Air Jets

High velocity shower jets in excess of 20 m/s to ensure efficient scrubbing action to remove particulate matter.

Stainless Steel Nozzles

Permanently lubricated direct drive centrifugal blowers used in conjunction with stainless steel air nozzles.

Programmable Operation

Operating modes can be programmed in the field.

Reliable Microprocessor Control System

Microprocessor controller supervises all functions.

H14 Filtration

The typical efficiency of H14 filter is 99.995% at 0.1 - 0.2 micron particles.

Pre-filtration

A disposable prefilter with 85% arrestance extends the life of the main filter.

Emergency Buttons

An emergency stop button is mounted on both sides of the shower.

Indicator Lights to Signal Door Status

Indicator lights mounted on both sides of the exterior of the air shower to regulate traffic flow, in and out of the cleanroom.

Durable Doors

Heavy-duty, durable doors with glass windows to permit visibility.

Powder-Coated Steel Construction

The air shower is constructed of electrogalvanized steel sheets with an abrasion-resistant oven-baked powder coated finish. (Optional: Stainless steel 304 construction)

Uniform Lighting

Light diffusers ensure uniform lighting throughout the chamber.

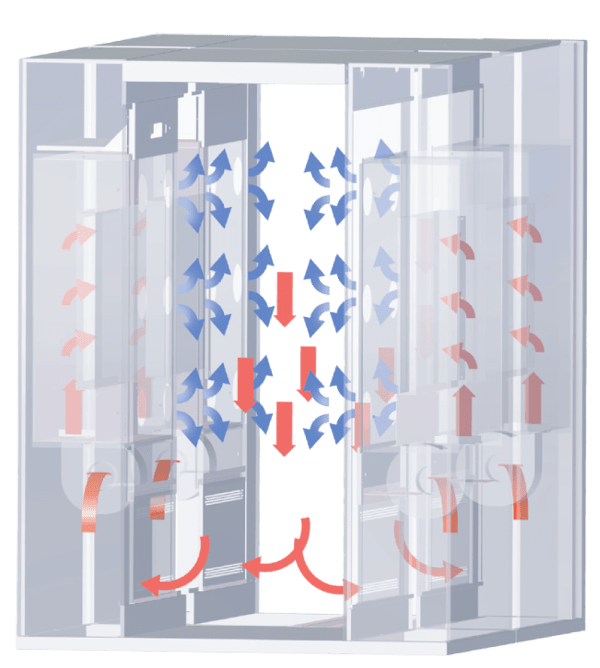

Principle

- Air is forced by the blower(s) through H14 filter(s) which are 99.995% efficient against particles of 0.1 - 0.2 microns.

- Filtered air is ejected through nozzles at high velocities into the chamber. These turbulent air streams disperse particulate matter on all surfaces.

- Dispersed particulate matter migrate with the air stream towards the lower areas in the air shower chamber. Air enters the blower supply plenum through pre-filter(s) installed at the base of the chamber.

- The air is continuously filtered and recirculated. The air shower is a self-contained device and does not exchange air with the environment it is placed in.

Accessories

- Emergency stop buttons (inside the EAS)

- Gauge for differential across filter monitoring

- Vertical shutter door